Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

20mm U-shape handle Framed Cabinet Door Aluminum Door Frame Glass Door Wardrobe Simple Style Type

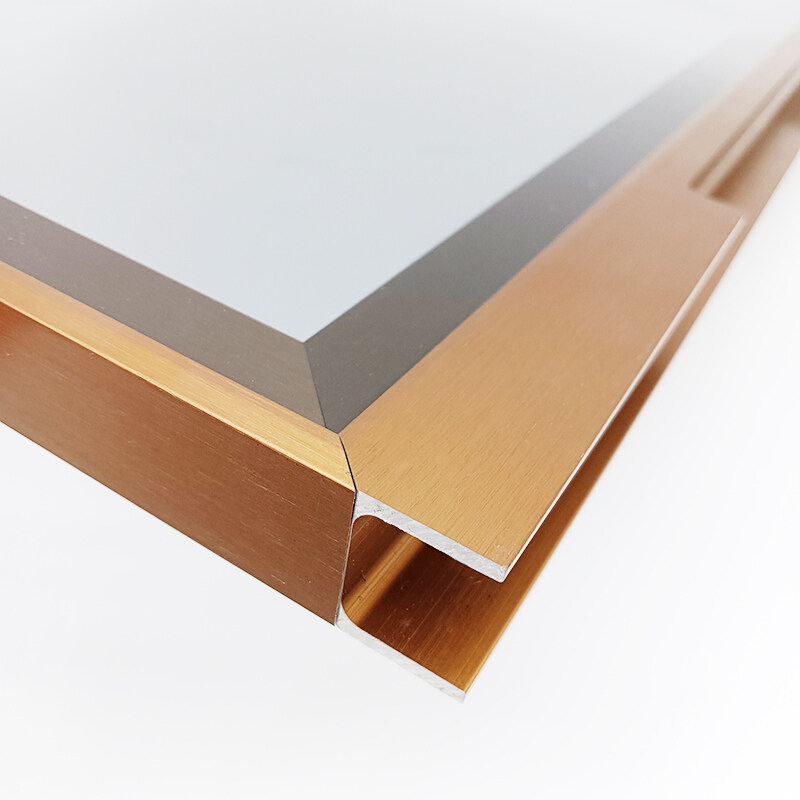

The frosted aluminum profile has a unique appearance, high strength and an excellent corrosion resistance. We do not use a bright aluminum alloy, which often causes light interference in the environment and conditions in architectural decoration.

Description of a 20mm U-shape Framed Cabinet Door

Cabinet doors are the most prominent feature of any kitchen or bathroom. They not only serve a functional purpose but also add to the overall aesthetics of the space. One of the most popular types of cabinet doors is the 20-mm U-shape handle-framed cabinet door.

Item Name:

20mm U-shaped handle frame cabinet door profile

Temper:

T5, T6

Surface Treatment:

Powder coating, electrophoresis, anodizing, wood grain, and mill finish

Color:

Brown, champagne, wooden colour, or customised

Shape:

Square, angle, flat, hollow, oval, triangle, U-profile, L-profile, F-profiles, G-profiles, or customised

Length:

Customised

Deep Processing:

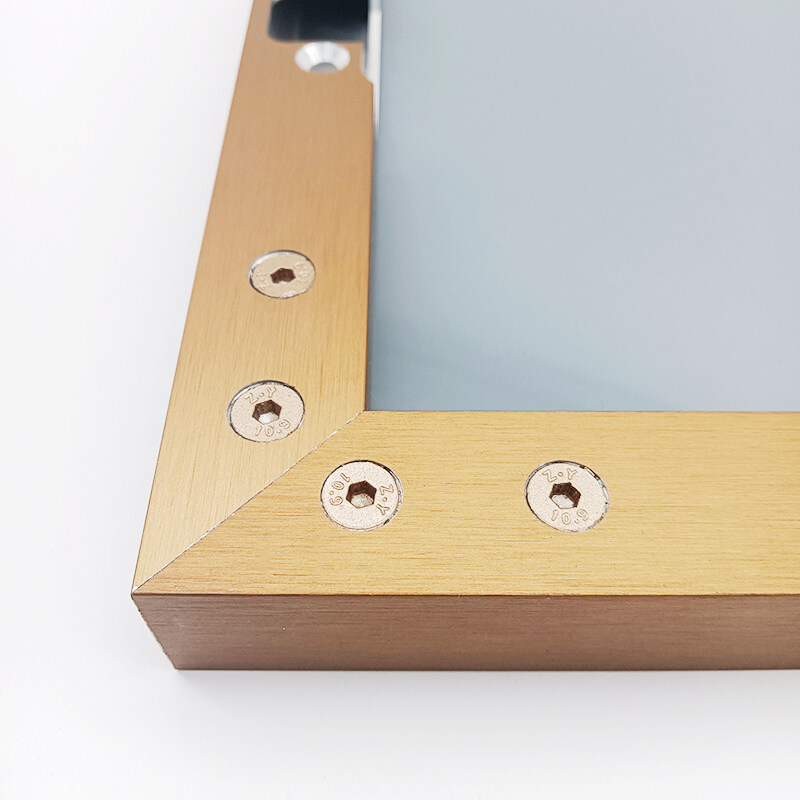

Cutting, drilling, punching, bending, and more

3D Design:

Designers in the design and development department use AutoCAD, 3D, PDF, JPEG, etc.

Engineering & Tooling:

Eight engineers in the mould shop use high-tonnage extruders, wire EDM, CNC, drilling machines, and more.

Quality Control:

Inspection at the site and before shipping using a testing machine.

Benefits of a 20mm U-shape Framed Cabinet Door

1. One of the primary benefits of the 20-mm U-shape handle-framed cabinet door is its aesthetic appeal. It provides a contemporary and minimalist look that complements any modern kitchen or bathroom.

2. Additionally, the U-shaped handle is ergonomic and makes it easy to open and close the cabinet door.

3. The door frame also provides extra support for the cabinet door, making it more sturdy and durable.

Surface Treatment of Aluminium Profiles:

- Frosted Fabric Profile: Ideal for architectural decoration, this profile avoids light interference and has a delicate and soft surface.

- Multi-Tone Surface-Treated Aluminium Profiles: Offers a variety of colors and decorative effects, achieved through chemical or mechanical polishing and oxidation.

- Electrophoretic Painted Aluminium Profiles: Has a soft surface that resists invasion from cement and mortar acid rain.

- Powder Electrostatic Spraying Aluminium Profiles: Characterized by excellent corrosion resistance and better acid and alkali salt spray resistance than oxidation coloring profiles.

- Plasma-Enhanced Electrochemical Surface Ceramicized Aluminium Profile: The most advanced processing technology in the world, this profile product is of good quality but has a high cost and can be colored according to needs.

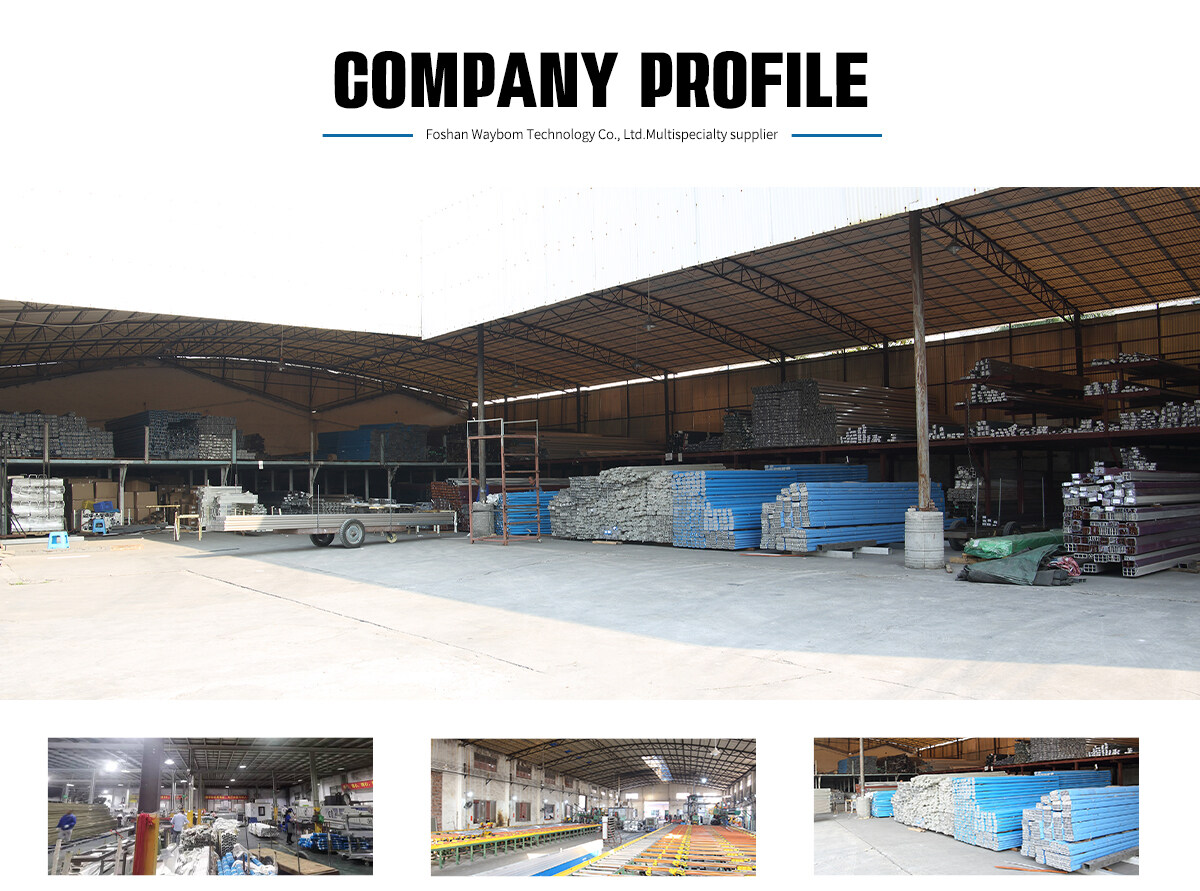

Our factory was established in 2008, covers an area of 56,368 square meters, has 176 employees. With 5 aluminum production lines, 20 CNC machining centers, 2 powder coating lines, several anodizing tanks, Polishing, brushing and sand blasting equipments, Well-established packaging and quality inspection system, our annual output of aluminum is 15000 tons, and more than 20,000 sets of finished products. We can satisfy your demands quickly from our stock or produce your own design. We do ODM and OEM.

We choose A0 degree aluminum ingot as raw material.

The most used 6063-T5 and 6061-T6 aluminum alloy comply with national standards GB/T5237.

We do extruding with designed moulds to get different shape of profiles.

The strength and toughness of the profiles are ensured by aging treatments.

Surface treatment like powder coating, anodizing and electrophosis are required to protect the profile and get good-looking surface.

We do offer machining services like milling, drilling, bending, threading, etc.

All products will be inspected strictly before packing.

After you place your order, we will check again and suggest you the best packaging method based on different shapes of products (including but not limited to kraft paper packaging/bubble wrap/wooden box packaging).

We provide different packages for different products to make sure the goods can stay good during long-time shipping. And we can do customization according to your requirement.

Usually we will use kraft paper, bubble wrap, plastic protective film, cartons, wood crate and pallet, ect.

Usually we need 15-45 days for production, and we would communicate with customers about all details for shipping a week earlier before goods are ready.

Either you have shipping agents or not, we can assist you to ship the goods and provide you documents for custom clearance. And door to door shipping is also available.